Frequently Asked Questions

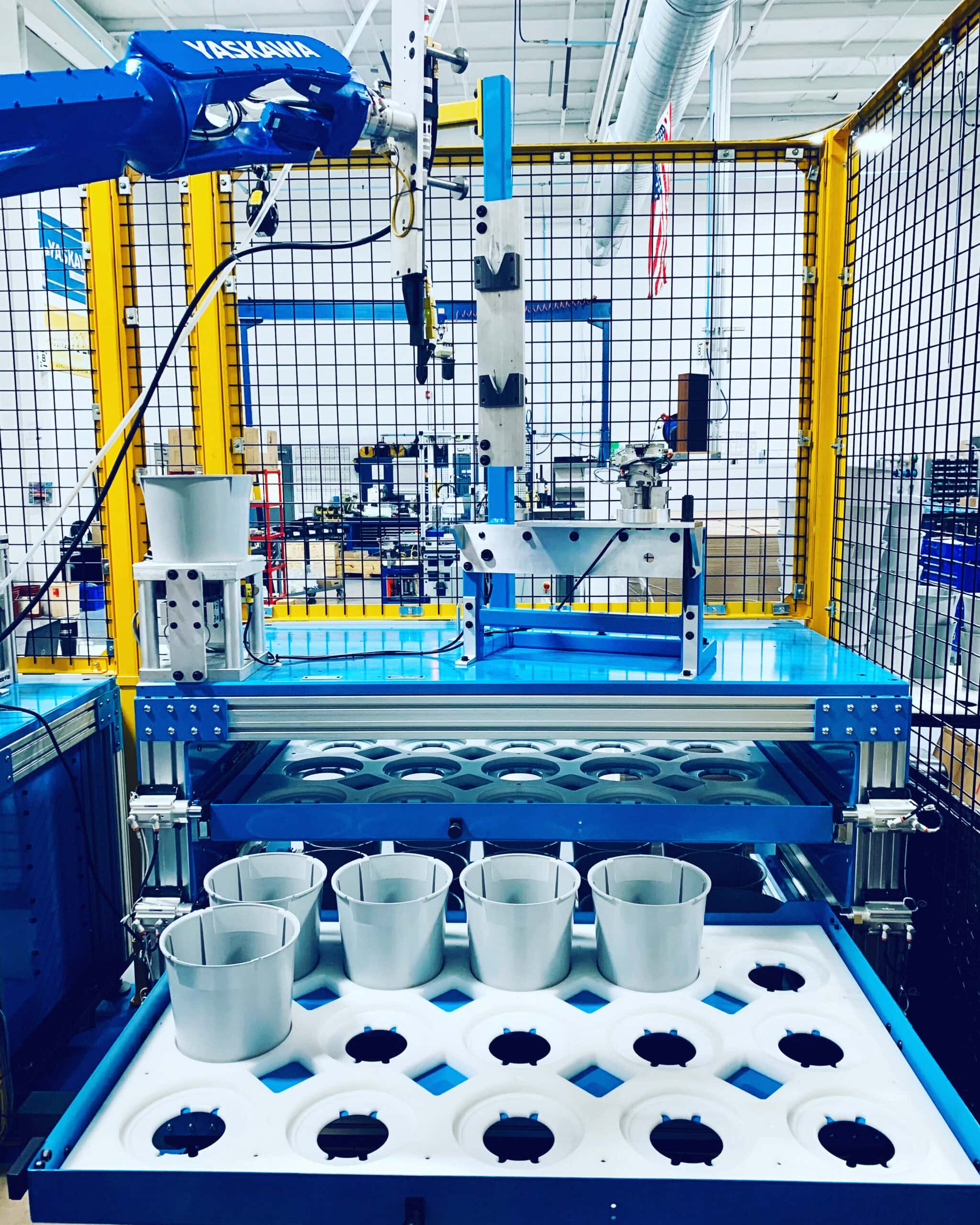

What types of automation solutions does Versatech offer?

Versatech offers a range of automation solutions, including assembly automation, machine tending, inspection and testing, and material handling, all tailored to enhance efficiency and reliability in complex manufacturing processes.

How does Versatech ensure efficiency in manufacturing processes?

Versatech ensures efficiency in manufacturing processes by designing customized automation solutions that enhance precision, streamline operations, and adapt to the specific needs of each application, ultimately improving overall productivity and reliability.

What is the process for requesting a quote for automation services?

The process for requesting a quote for automation services involves filling out our online inquiry form or contacting our sales team directly. We will assess your requirements and provide a tailored quote based on your specific needs.

What industries benefit from Versatechs automation solutions?

Various industries benefit from Versatech's automation solutions, including automotive, electronics, pharmaceuticals, food and beverage, and consumer goods. Our tailored systems enhance efficiency and reliability across these sectors, addressing their unique manufacturing challenges.

How does Versatech customize automation for clients?

Versatech customizes automation for clients by conducting thorough assessments of their unique manufacturing processes, collaborating closely to design tailored solutions that enhance efficiency, precision, and reliability in their specific applications.

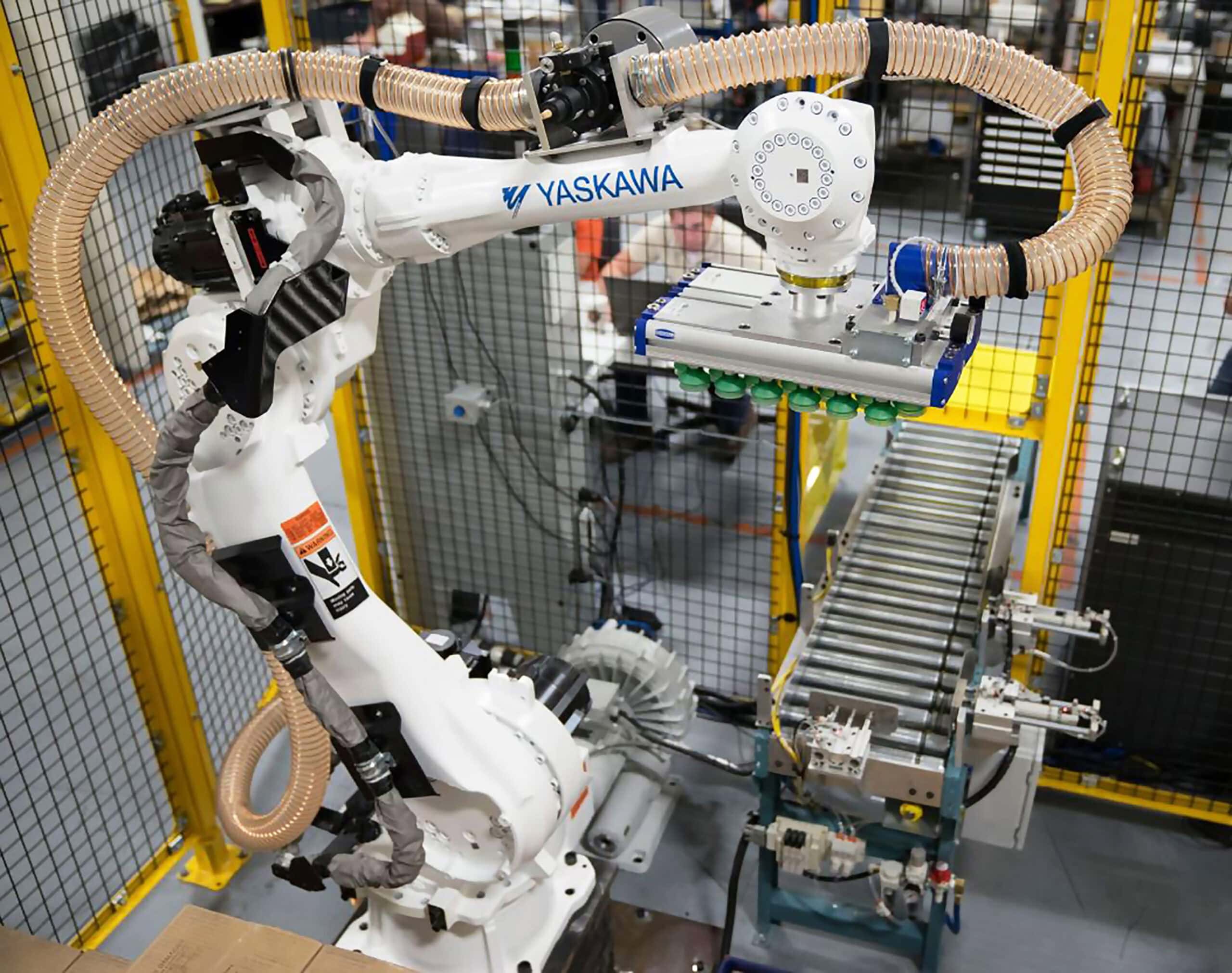

What technologies are used in Versatechs automation?

The technologies used in Versatech's automation include advanced robotics, machine vision systems, artificial intelligence, and IoT integration, all designed to enhance precision, efficiency, and adaptability in manufacturing processes.

How can automation improve production efficiency?

Automation improves production efficiency by streamlining processes, reducing manual errors, and enhancing consistency. By implementing automated systems, manufacturers can achieve higher output, faster cycle times, and better resource management, ultimately leading to increased productivity and cost savings.

What are the key features of Versatechs systems?

The key features of Versatech's systems include custom engineering, high precision, adaptability for various manufacturing processes, and comprehensive automation solutions such as assembly automation, machine tending, inspection and testing, and material handling.

How does Versatech handle project timelines?

Versatech manages project timelines through a structured approach that includes thorough planning, regular progress assessments, and effective communication with clients to ensure timely delivery of customized automation solutions.

What support does Versatech offer post-installation?

Versatech offers comprehensive post-installation support, including ongoing maintenance, troubleshooting assistance, and training programs to ensure optimal performance of your automation solutions. Our dedicated team is committed to maximizing your system's efficiency and reliability.

How does Versatech ensure system reliability?

Versatech ensures system reliability through rigorous testing, quality control processes, and custom engineering tailored to specific manufacturing needs, resulting in robust automation solutions that consistently perform under demanding conditions.

What is the role of machine tending in automation?

The role of machine tending in automation is to efficiently manage the loading and unloading of materials in manufacturing processes, enhancing productivity and ensuring consistent operation of machinery while reducing manual labor and human error.

How does Versatech approach assembly automation?

Versatech approaches assembly automation by designing tailored solutions that enhance efficiency and precision, utilizing advanced technology to meet the specific needs of each manufacturing process. Our focus is on custom engineering to ensure optimal performance and reliability.

What are the advantages of custom automation solutions?

The advantages of custom automation solutions include tailored designs that meet specific manufacturing needs, improved efficiency and reliability, and enhanced adaptability to complex processes, ultimately leading to increased productivity and reduced operational costs.

How does Versatech integrate inspection and testing?

Versatech integrates inspection and testing by embedding advanced quality control systems within our automation solutions, ensuring real-time monitoring and analysis to enhance product reliability and adherence to specifications throughout the manufacturing process.

What materials are handled by Versatechs systems?

Versatech's systems handle a diverse range of materials, including metals, plastics, composites, and various assemblies, ensuring tailored automation solutions for different manufacturing processes and applications.

How can automation reduce operational costs?

Automation can significantly reduce operational costs by streamlining processes, minimizing labor expenses, and enhancing efficiency. By reducing human error and increasing production speed, companies can achieve higher output with lower resource consumption.

What is the typical lead time for automation projects?

The typical lead time for automation projects varies based on complexity, but generally ranges from 8 to 16 weeks. This timeline includes design, engineering, and implementation phases tailored to meet specific manufacturing needs.

How does Versatech assess client needs for automation?

Versatech assesses client needs for automation through a comprehensive consultation process, analyzing specific manufacturing challenges and objectives to tailor solutions that enhance efficiency and reliability in their operations.

What training is provided for automation systems?

The training provided for automation systems includes comprehensive sessions on system operation, troubleshooting, and maintenance, ensuring users are well-equipped to manage and optimize their automation solutions effectively.

How does Versatech ensure safety in automation?

Versatech ensures safety in automation by implementing rigorous safety standards, conducting thorough risk assessments, and integrating advanced safety features into all automation solutions, thereby protecting both operators and equipment in manufacturing environments.

What are the latest trends in industrial automation?

The latest trends in industrial automation include the rise of artificial intelligence and machine learning, increased integration of the Internet of Things (IoT), and a focus on collaborative robotics to enhance efficiency and flexibility in manufacturing processes.

How does Versatech support scalability in automation?

Versatech supports scalability in automation by designing flexible systems that can be easily adapted or expanded to accommodate changing production demands, ensuring efficient integration with existing processes while maintaining high performance and reliability.

What is the impact of automation on workforce?

The impact of automation on the workforce includes increased efficiency and productivity, as well as potential job displacement. However, it also creates opportunities for new roles focused on managing and maintaining automated systems, ultimately transforming the nature of work.

How does Versatech maintain quality control in processes?

Versatech maintains quality control in processes through rigorous testing, continuous monitoring, and adherence to industry standards, ensuring that all automation solutions meet high precision and reliability requirements.

What are common challenges in implementing automation?

Common challenges in implementing automation include the high initial costs, integration with existing systems, workforce resistance to change, and the need for ongoing maintenance and support to ensure optimal performance.

How does Versatech evaluate system performance?

Versatech evaluates system performance through rigorous testing and data analysis, focusing on efficiency, reliability, and precision to ensure that automation solutions meet the specific needs of each manufacturing process.

What innovations are being developed in automation?

Innovations being developed in automation include advanced robotics, artificial intelligence integration, and smart sensors, which enhance flexibility, efficiency, and precision in manufacturing processes while enabling real-time data analysis and improved decision-making.

How can clients track project progress with Versatech?

Clients can track project progress with Versatech through regular updates, detailed project timelines, and access to our project management tools, ensuring transparency and effective communication throughout the automation solution development process.

What are the environmental benefits of automation?

The environmental benefits of automation include reduced energy consumption, minimized waste generation, and enhanced resource efficiency. By optimizing manufacturing processes, automation helps lower the carbon footprint and promotes sustainable practices in industrial operations.