Frequently Asked Questions

How can automation improve material handling processes?

Automation can significantly improve material handling processes by enhancing efficiency, reducing labor costs, and minimizing errors. Automated systems streamline operations such as packing and depalletizing, leading to increased throughput and better resource utilization.

What are the benefits of using robotic systems in packaging?

The benefits of using robotic systems in packaging include increased efficiency, reduced labor costs, enhanced precision, and improved safety. These systems streamline operations, allowing for faster and more consistent packaging processes, ultimately boosting productivity.

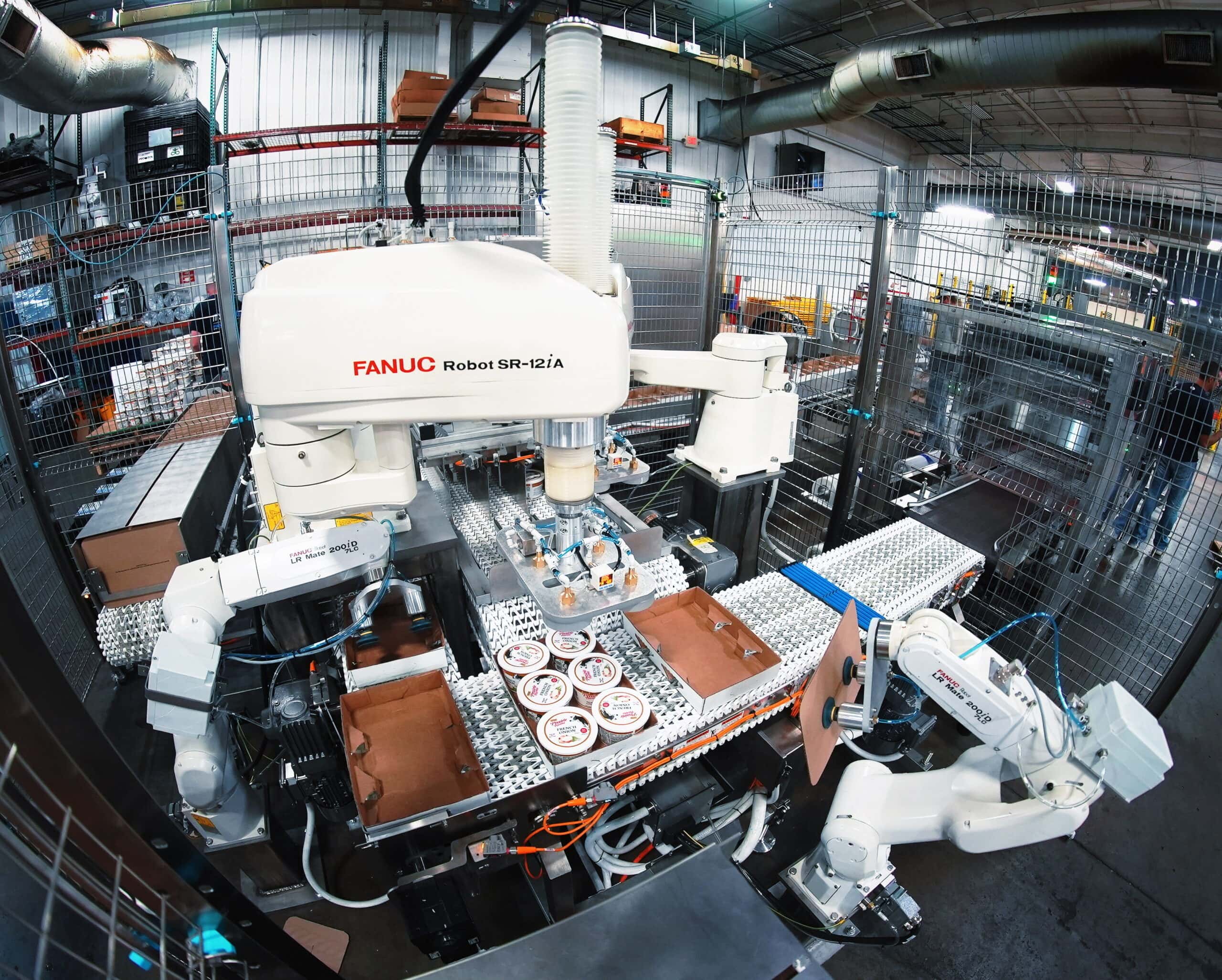

How does Versatechs automated handling system work?

The automated handling system at Versatech works by integrating advanced robotic technologies to efficiently move, pack, and organize products, utilizing sensors and software to optimize workflow and enhance operational efficiency.

What industries can benefit from automated material handling solutions?

Various industries can benefit from automated material handling solutions, including manufacturing, food and beverage, pharmaceuticals, and logistics. These sectors experience enhanced efficiency, reduced labor costs, and improved product handling through automation.

What specific services does Versatech offer for material handling?

Versatech offers a range of services for material handling, including robotic case erecting, packing, and depalletizing solutions designed to enhance efficiency and streamline operations across various industries.

How does automation enhance material handling efficiency?

Automation enhances material handling efficiency by streamlining processes, reducing manual labor, and minimizing errors. By implementing automated systems, businesses can achieve faster product movement, improved accuracy in packing, and overall higher throughput in their operations.

What advantages do robotic systems provide in packaging?

The advantages of robotic systems in packaging include increased efficiency, precision, and consistency. They reduce labor costs, minimize human error, and enhance throughput, ultimately leading to improved productivity and streamlined operations in material handling processes.

Which industries utilize automated handling solutions most?

The industries that utilize automated handling solutions most include manufacturing, food and beverage, pharmaceuticals, and logistics. These sectors benefit significantly from enhanced efficiency, accuracy, and productivity in their material handling processes.

What features distinguish Versatechs automated systems?

The features that distinguish Versatech's automated systems include advanced robotics for precision, customizable solutions tailored to specific industry needs, and seamless integration with existing workflows to enhance efficiency and productivity in material handling and packaging.

How can automation reduce labor costs in handling?

Automation can significantly reduce labor costs in handling by streamlining processes, minimizing manual intervention, and increasing throughput. This leads to lower staffing requirements and enhanced operational efficiency, ultimately resulting in cost savings for businesses.

What challenges are faced in automated material handling?

The challenges faced in automated material handling include high initial investment costs, system integration complexities, and the need for ongoing maintenance and updates to keep up with technological advancements and operational demands.

How does Versatech ensure system reliability and safety?

Versatech ensures system reliability and safety through rigorous testing, adherence to industry standards, and the integration of advanced safety features in our automation solutions, guaranteeing optimal performance and minimizing risks in material handling and packaging processes.

What technologies are used in robotic packaging systems?

The technologies used in robotic packaging systems include advanced robotics, vision systems, artificial intelligence, and automation software, all of which enhance precision, efficiency, and adaptability in packaging processes.

How can businesses assess their material handling needs?

Businesses can assess their material handling needs by evaluating their current processes, identifying inefficiencies, analyzing product flow, and determining specific requirements for automation solutions tailored to their operational goals.

What is the ROI of implementing automation solutions?

The ROI of implementing automation solutions is significant, as it enhances operational efficiency, reduces labor costs, and increases throughput, ultimately leading to higher profitability and faster return on investment for businesses in material handling and packaging.

How does automation impact product quality in handling?

Automation significantly enhances product quality in handling by reducing human error, ensuring consistent processes, and maintaining precise control over operations. This leads to improved accuracy in product handling and minimizes damage during packaging and transportation.

What training is required for operating automated systems?

The training required for operating automated systems includes understanding system components, safety protocols, and operational procedures, along with hands-on experience to ensure effective and safe management of the automation processes.

How can automation streamline supply chain processes?

Automation can streamline supply chain processes by enhancing efficiency through the use of robotic systems and automated workflows, reducing manual labor, minimizing errors, and improving speed in tasks such as packing, sorting, and inventory management.

What are the latest trends in material handling automation?

The latest trends in material handling automation include increased integration of artificial intelligence and machine learning, the adoption of collaborative robots (cobots), and enhanced data analytics for real-time decision-making, all aimed at improving efficiency and flexibility in operations.

How does Versatech customize solutions for different clients?

Versatech customizes solutions for different clients by conducting thorough assessments of their specific needs and operational workflows, allowing us to design and implement tailored automation systems that enhance efficiency and meet unique requirements.