Frequently Asked Questions

What are the benefits of automated machine tending?

The benefits of automated machine tending include increased efficiency, reduced labor costs, enhanced repeatability, and improved integration with CNC operations. These systems streamline production processes, allowing for greater output and consistency in manufacturing.

How does workholding improve manufacturing efficiency?

Workholding improves manufacturing efficiency by securely positioning and stabilizing parts during machining processes, which enhances repeatability, reduces setup times, and minimizes errors. This leads to increased productivity and consistent quality in production.

What types of machine tending systems are available?

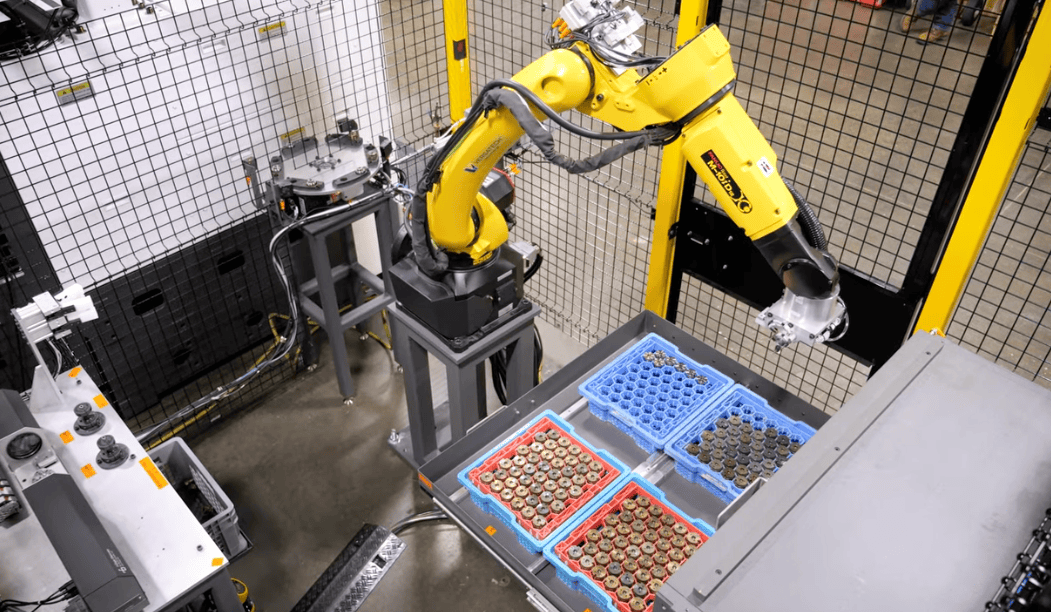

The types of machine tending systems available include robotic arms for automated loading and unloading, collaborative robots for safe human-robot interaction, and custom fixtures designed for specific machining tasks, all aimed at enhancing manufacturing efficiency.

How can I integrate robots with CNC operations?

Integrating robots with CNC operations involves designing automated systems that seamlessly connect robotic arms to CNC machinery. This enhances efficiency by automating loading, unloading, and part handling, ultimately improving production speed and consistency.

What features should I look for in workholding fixtures?

The key features to look for in workholding fixtures include versatility for various part shapes, precision for repeatability, ease of integration with CNC machines, and durability to withstand manufacturing conditions.

How does automation reduce labor content in manufacturing?

Automation reduces labor content in manufacturing by streamlining processes, minimizing manual intervention, and increasing production speed. This leads to enhanced efficiency, allowing manufacturers to allocate their workforce to more value-added tasks while robots handle repetitive operations.

What industries benefit from machine tending solutions?

The industries that benefit from machine tending solutions include automotive, aerospace, medical device manufacturing, and general machining. These sectors leverage automation to enhance efficiency, reduce labor costs, and improve precision in their production processes.

How can workholding fixtures enhance repeatability?

Workholding fixtures enhance repeatability by securely positioning parts during machining processes, ensuring consistent alignment and reducing variability. This leads to improved accuracy and quality in manufacturing, ultimately boosting overall production efficiency.

What is the role of automation in manufacturing?

The role of automation in manufacturing is to enhance efficiency, reduce labor costs, and improve precision in production processes. By integrating automated systems, manufacturers can achieve higher output and consistency while minimizing human error.

How do I choose the right machine tending system?

Choosing the right machine tending system involves assessing your specific manufacturing needs, including the type of machinery, production volume, and desired automation level. Collaborate with experts to ensure optimal integration and efficiency.

What are the latest trends in workholding technology?

The latest trends in workholding technology include the integration of smart sensors for real-time monitoring, the use of modular and adaptable fixtures for increased flexibility, and advancements in automation that enhance precision and efficiency in manufacturing processes.

How can automated machine tending increase productivity?

Automated machine tending increases productivity by streamlining operations, reducing labor costs, and enhancing consistency in manufacturing processes. This integration allows for continuous operation, minimizing downtime and maximizing output efficiency.

What challenges are associated with machine tending?

The challenges associated with machine tending include ensuring proper integration with existing machinery, managing the complexity of automation systems, and addressing the need for precise programming and maintenance to achieve optimal efficiency and reliability.

How do workholding solutions impact production costs?

Workholding solutions significantly impact production costs by enhancing efficiency and reducing cycle times. By improving part stability and repeatability, these systems minimize scrap rates and labor expenses, ultimately leading to cost savings in manufacturing processes.

What is the future of machine tending automation?

The future of machine tending automation is characterized by increased integration of advanced robotics, artificial intelligence, and machine learning, leading to enhanced efficiency, flexibility, and productivity in manufacturing processes.

How can I optimize my workholding setup?

Optimizing your workholding setup involves assessing fixture design for versatility, ensuring precise alignment, and integrating automation solutions to enhance repeatability and efficiency in your manufacturing processes.

What are common applications for machine tending?

Common applications for machine tending include loading and unloading CNC machines, automated assembly lines, and material handling processes. These systems enhance efficiency, reduce labor costs, and improve production consistency across various manufacturing environments.

How does Versatech™ support automation integration?

Versatech™ supports automation integration by designing custom machine tending systems and workholding fixtures that seamlessly interface with CNC operations, enhancing efficiency and ensuring reliable performance in manufacturing processes.

What are the key components of machine tending systems?

The key components of machine tending systems include robotic arms for handling parts, workholding fixtures for secure part placement, and integration software that connects the system with CNC machines to streamline operations and improve efficiency.

How can I improve my workholding design?

Improving your workholding design involves optimizing fixture geometry for better part stability, selecting appropriate materials for durability, and ensuring compatibility with your CNC machinery. Additionally, consider automation integration to enhance efficiency and repeatability in your manufacturing processes.

What safety considerations exist for machine tending?

Safety considerations for machine tending include ensuring proper guarding of machinery, implementing emergency stop mechanisms, providing adequate training for operators, and maintaining clear communication protocols to prevent accidents and injuries during automated processes.

How does machine tending affect cycle times?

Machine tending significantly affects cycle times by automating the loading and unloading processes, which minimizes downtime and maximizes machine utilization. This leads to faster production rates and improved overall efficiency in manufacturing operations.

What customization options are available for workholding?

Customization options for workholding include tailored designs for specific parts, adjustable fixtures for varying sizes, and integration with existing machinery to enhance efficiency and flexibility in manufacturing processes.

How can I evaluate machine tending system performance?

Evaluating machine tending system performance involves analyzing key metrics such as cycle time, uptime, and overall equipment effectiveness (OEE). Regularly monitoring these factors will help identify areas for improvement and ensure optimal efficiency in your manufacturing processes.

What are the advantages of custom workholding fixtures?

The advantages of custom workholding fixtures include enhanced precision, improved repeatability, and optimized workflow tailored to specific manufacturing needs, ultimately leading to increased efficiency and reduced production costs.

How does automation influence workforce requirements?

Automation influences workforce requirements by streamlining processes, which can reduce the need for manual labor while simultaneously increasing the demand for skilled workers to manage and maintain automated systems.

What is the impact of machine tending on quality?

The impact of machine tending on quality is significant. By automating the handling of parts, machine tending systems enhance precision, reduce human error, and ensure consistent production standards, ultimately leading to improved product quality and reliability.

How can I train staff for machine tending systems?

Training staff for machine tending systems involves providing hands-on experience with the equipment, offering comprehensive technical training, and utilizing simulation tools to enhance understanding of automation processes and safety protocols.

What are the maintenance needs for workholding fixtures?

The maintenance needs for workholding fixtures include regular inspections for wear and tear, cleaning to remove debris, and lubrication of moving parts to ensure optimal performance and longevity.