Pushing automation forward — by design

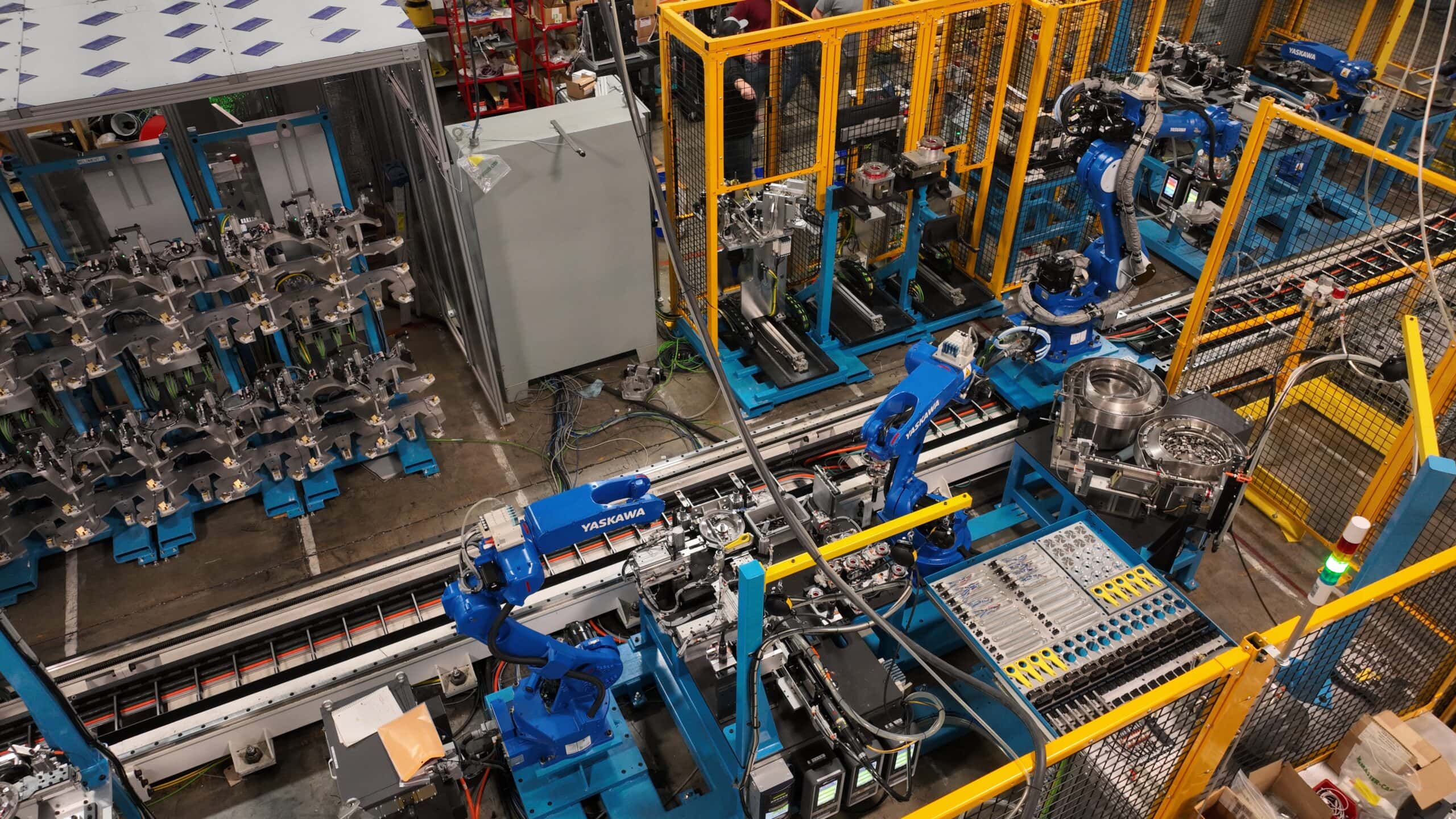

Since 2008, Versatech™ has engineered automation systems that solve complex manufacturing challenges. The lion’s share of components are designed and manufactured in-house at our Effingham, IL, facility, giving us full control over quality and integration.

BEGINNING

Built from the ground up

Versatech was founded by engineers with a goal to solve real production problems with smarter, more reliable automation. From our earliest systems to today’s multi-robot lines, we’ve been grounded in practical design and technical depth.

EVOLUTION

From custom builds to complete systems

Our work spans industries, from medical and aerospace to automotive and consumer goods. With robotics, vision and motion control integrated from the start, we’ve grown into a trusted partner for engineered automation at scale.

FUTURE-FORWARD

Part of something bigger

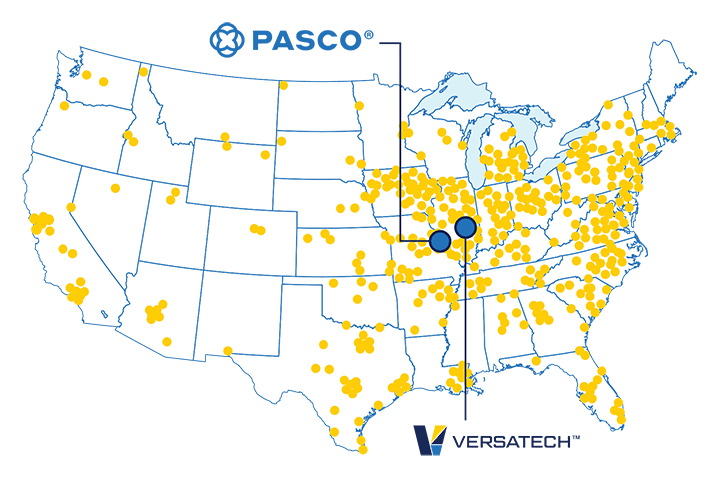

As part of Pasco Systems Corp, we’re helping manufacturers solve end-to-end challenges with unified, intentional automation. Together with PASCO®, we design systems that adapt to workforce shifts, quality demands and the future of production itself.

MISSION

At Versatech, we design and build complex automation you can trust by committing to:

UNCOMPROMISING QUALITY

SAFETY WITHOUT EXCEPTION

EXPLORE OUR FACILITY

Versatech’s facility and resources are designed to support complex automation from design through commissioning and the lifecycle of a system. Our offices and manufacturing space allow for growth, reconfiguration and full system builds under one roof. By keeping critical work in-house, we maintain consistency and accountability throughout each project.

Located in the heart of Illinois, our facility provides direct access to multiple major interstates, supporting efficient shipping, receiving and distribution across the U.S. Our infrastructure supports recessed docks, oversized load access and coordinated freight handling to meet a wide range of system requirements.

Our in-house manufacturing, machining, quality and finishing capabilities are supported by trusted vendor relationships when required. This combination allows us to deliver complete systems with control over quality, timelines and execution.

Key capabilities include:

- Multiple recessed docks and oversized load access

- In-house and outsourced rigging and freight coordination

- Full machine build, run-off and quality verification areas

- Machining, production, warehouse and quality lab resources

- In-house and partner finishing processes including heat treat, coating and plating

- Dedicated spaces for client meetings, training and collaboration

EXPLORE OUR FACILITY

Versatech’s facility and resources are designed to support complex automation from design through commissioning and the lifecycle of a system. Our offices and manufacturing space allow for growth, reconfiguration and full system builds under one roof. By keeping critical work in-house, we maintain consistency and accountability throughout each project.

Located in the heart of Illinois, our facility provides direct access to multiple major interstates, supporting efficient shipping, receiving and distribution across the U.S. Our infrastructure supports recessed docks, oversized load access and coordinated freight handling to meet a wide range of system requirements.

Our in-house manufacturing, machining, quality and finishing capabilities are supported by trusted vendor relationships when required. This combination allows us to deliver complete systems with control over quality, timelines and execution.

Key capabilities include:

- Multiple recessed docks and oversized load access

- In-house and outsourced rigging and freight coordination

- Full machine build, run-off and quality verification areas

- Machining, production, warehouse and quality lab resources

- In-house and partner finishing processes including heat treat, coating and plating

- Dedicated spaces for client meetings, training and collaboration

A PASCO SYSTEMS CORP BRAND

In 2023, PASCO® and Versatech™ were unified under the Pasco Systems Corp umbrella as two complementary brands. Manufacturers now benefit from complete, end-to-end automation, combining Versatech’s upstream process capabilities with PASCO’s downstream packaging expertise.

St. Louis Facility

2600 S Hanley Rd #430

St. Louis, MO. 63144

Office: 314.781.2212

Effingham Facility

1609 W. Wernsing Ave.

Effingham, IL. 62401

Office: 217.342.3500